Compressed Air Leaks and Ultrasonic Inspection

-By Paul Tashian, Superior Signal Company LLC

Efficiency can be measured or defined in many ways. Regardless of your definition, non-efficient systems and processes can seriously effect the economics of any facility. Efficiency can be expressed as the ratio of input power to output power. It is an indicator of the "tightness" of the plant. Input power includes all the power consumed to reach a level of output. Therefore, the higher the input power for the same level of output, the lower the efficiency, and the profits!

Efficiency can be measured or defined in many ways. Regardless of your definition, non-efficient systems and processes can seriously effect the economics of any facility. Efficiency can be expressed as the ratio of input power to output power. It is an indicator of the "tightness" of the plant. Input power includes all the power consumed to reach a level of output. Therefore, the higher the input power for the same level of output, the lower the efficiency, and the profits!

How can input power be minimized? One of the easiest ways is to avoid wasting it. One of the main culprits of energy waste are compressed air leaks. Air leaks are very common, and can easily go undetected. In order to stop the waste, leaks must be found and fixed. Remarkably, this is a relatively simple process, providing the people responsible for it have the tools to do the job,

Most of us already understand the importance of locating and repairing air leaks and the incredible costs that can be associated with such waste - easily 10's of thousands of dollars in most plants, 100’s of thousands in some. Estimates given by the US Department of Energy show that in plants with no routine leakage programs, roughly 30% of compressed air is being lost Not only do leaks add to everyday operating costs, but will also ultimately affect the life of your compressor(s). Ultrasonic inspection is the most effective way to locate these costly leaks.

For many years ultrasonic leak detection techniques have been used in plant maintenance programs to reduce energy costs, and increase equipment reliability. Compressed air leak detection has proved to be one of the most popular uses for this versatile technology. In our daily interaction with those responsible for maximizing plant efficiency, however, experience shows that many who are using ultrasonics don't really understand the physical principles behind the operation of these instruments. This can result in a false sense of security, and unrealistic expectations. This article will describe the physical basis of ultrasonic inspection, and offer some tips on setting up your own leak detection program.

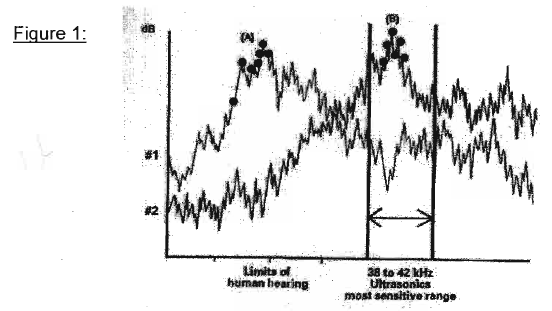

Ultrasonics, as the name implies, is sound above the human hearing range. The sound that you consider "noise" in your plant covers a wide range of sound frequencies. The audible sound that you hear is only a small part of the total spectrum of sound that actually exists With the use of an ultrasonic detector, `high frequency ultrasound is translated into the audible range where it can be heard through a headset. By identifying this high frequency sound, plant maintenance crews can locate sources of wasted energy as well as diagnose a variety of potential maintenance nightmares. In an industrial facility, friction in moving equipment and turbulence in the flow of fluids and Basses emit high levels of ultrasound. Pressurized leaks in pneumatic air lines, steam lines, and vacuum leaks emit ultrasound, as well as internal leaks in valves, steam traps, and hydraulic systems. Ultrasonic inspection takes you into a different world of hearing. Figure "1 shows a suggested sound spectrum of an air leak (line #2). The sound your unaided ear can detect (area A) is virtually non-existent to an ultrasonic detector. The most" intense (loudest) sound produced by the leak is in the ultrasonic range (area B). This is the sound ultrasonic detectors allow you to hear. If you've never used and ultrasonic leak detector before, you will be amazed at how effective this technique is at hearing leaks, even in the loudest of industrial environments.

Background noise, and ultrasonic technologies; While the background noise in your plant may seem overwhelming to your naked ear, in many cases the sound present in the ultrasonic range (Area B) is insignificant, and does not hinder leak detection. But what about when there is a high level of ultrasonic background noise? Pressure relief valves, nozzles, tooling and other operating equipment use air, and can create ultrasonic "noise" which is also detected by the instrument. This is the greatest obstacle to ultrasonic leak detection. How is it possible to detect and isolate the sound of a leak with all this competing background noise? Remember the louder the background interference, the louder the leak must be in order to be detected. Reducing the sensitivity of your instrument, and positioning the sensor so those sources of background noise are behind you, will be a great help in finding leaks in loud areas- In addition, most ultrasonic detectors on the market today use one of two different electronic techniques for frequency selection and noise suppression.

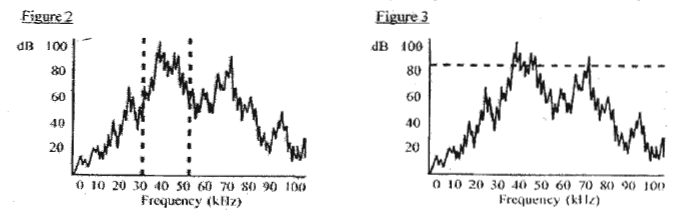

The first is called Heterodyning. This technique selects a narrow range or "window" of sound in the ultrasonic range and converts it to a set range of sonic frequencies (figure 2). Some Heterodyne type detectors are tunable, allowing the user to adjust this narrow "window" up and down throughout the complete range of the instrument (much like tuning a radio). The idea is that the user can hopefully tune out the major source of background noise interference and focus in on the sound of the leak. The problem with this technique is that you never know exactly where the dominant leak frequency will be. You may be tuning out leaks just as an effort is being made to find them.

The other technology used in ultrasonic detectors is called Dynamic Noise Discrimination (or DNDTM). With this technique no frequency searches are required. A sensitivity adjustment sets the threshold or intensity level a signal must have to be -detected (figure 3). These instruments are constantly analyzing the sound being received, and when the detector -crosses the path of a leak, it automatically locks on to the unique characteristics of the dominant leak sound Very little sound is transmitted to the headset until the "smart" electronics identify a signal, then it becomes very clear.

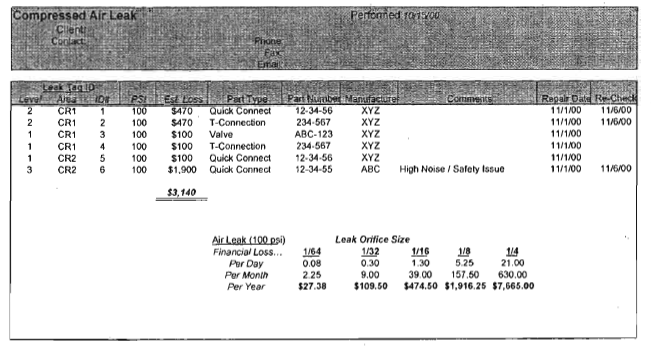

The Leak Survey; A leak survey may be part of a more thorough evaluation of the system including review of pipe sizing, pressure regulation, filtering, etc. The leak survey consists of a systematic ultrasonic scan of the entire system. When `leaks are found it is important to tag and record them. Leaks should be identified by location, severity, and type of part that is leaking You may find a trend in a particular type .of hose fitting, or quick connect that leaks more frequently than others. Below is-a sample of what your record of leaks might look like.

This chart uses a three-part identification for each leak. It contains codes which identify the severity of the leak (level 1, 2, or 3), the general location of the leak (compressor room 1"CRI"), and a unique sequential ID (1,2,3,etc). Once this is set up in a database the information can be sorted by location or severity so that repairs can be planned in a logical order.

Quantifying leaks; Some manufactures of ultrasonic detectors promote using the intensity meter on the instrument as a gauge for quantifying leaks. If you plan on doing this, keep in mind that this method is a very loose estimation. It is physically impossible_ to quantify air loss in a plant environment using an instrument that detects sound. It is the amount of turbulence present at a leak site that determines how much ultrasonic sound will be produced by a given leak. The amount of turbulence present at the leak site is a function of the size of the orifice, the pressure behind the leak, the shape, or physical geometry of the orifice and the type of pipe or container holding the gas - to name a few factors.

Leaks come in all shapes and sizes, and it is quite possible for a smaller leak to create more turbulence (and sound) than a larger leak. Imagine an open garden hose with water flowing out. There is a tremendous loss of water here, but very little sound, spray, or turbulence. Now put your thumb over the end of the hose. Water is now being forced through a small orifice, and it becomes turbulent. Much less flow than the open hose, but much more turbulent.

There are other factors that affect the intensity reading on your instrument as well. Some of these include the background noise level, the sensitivity setting, the frequency setting, the distance from the leak, the angle of approach, and even the relative humidity in the atmosphere. You can actually get higher readings on dryer days. All these things will effect the meter's response to a given leak signal.

The severity of leaks should be graded using a combination of (1) sound intensity from your ultrasonic instrument, (2) visual inspection, and (3) physically feeling the flow with your hand, if this can be done safely. Although probably more conservative than the ultrasonic intensity meter - only approach, it is a good way of estimating your losses.

If your plant uses compressed air, an ultrasonic leak survey is a good idea. It is a great way maintenance departments can help strengthen the company's bottom line, and prove it! Cost justifying a leak detection program is not difficult, simply because very lime investment is required, and the benefits are measurable. If is easy to get started, requiring only a minimal investment in equipment, and very little if any, training.