The heart of a refrigeration system is the thermal expansion valve or TXV. When TXVs are malfunctioning, the performance of a refrigeration system can be severely affected. However, diagnosing TXV problems is not an easy task. It requires instruments and gauges to be hooked up to the system and calculations (superheat) made to determine if the TXV functions properly. This process is time consuming and requires knowledge and skill, but it can be done in minutes using a Superior AccuTrak® VPE Ultrasonic Leak Detector equipped with its patented Touch Probe.

The heart of a refrigeration system is the thermal expansion valve or TXV. When TXVs are malfunctioning, the performance of a refrigeration system can be severely affected. However, diagnosing TXV problems is not an easy task. It requires instruments and gauges to be hooked up to the system and calculations (superheat) made to determine if the TXV functions properly. This process is time consuming and requires knowledge and skill, but it can be done in minutes using a Superior AccuTrak® VPE Ultrasonic Leak Detector equipped with its patented Touch Probe.

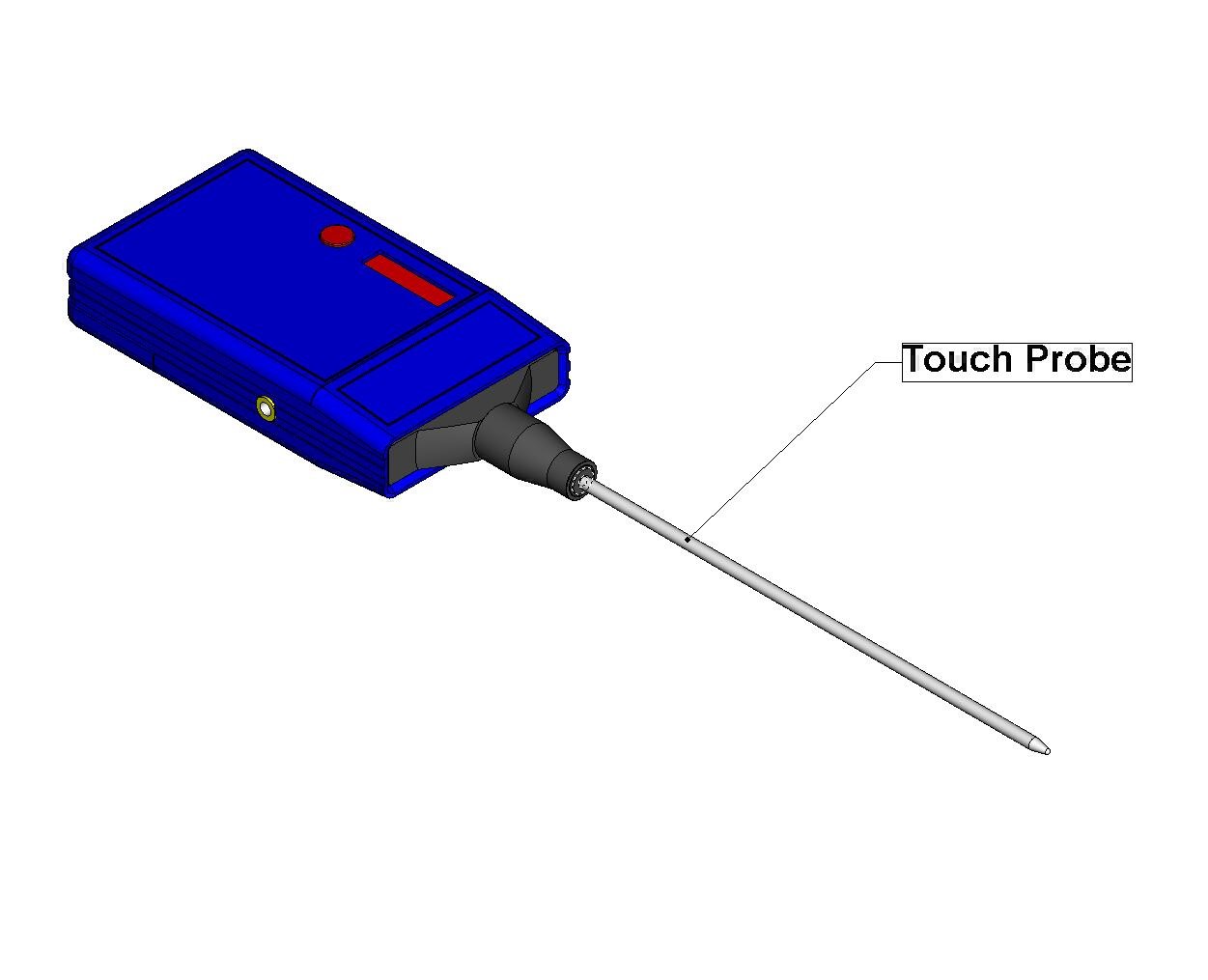

When fluid or gas leaks through the seat of a valve, ultrasonic waves are generated that propagate through the valve body. Ultrasonic leak detectors detect ultrasonic noise and convert that ultrasound into an audible sound we can hear. By touching a TXV valve with the VPE Touch Probe, a technician can listen to the internal function of the valve and quickly determine if it is operating properly.

How to Test a TXV:

To determine if a TXV is operating properly, first free the capillary sensor bulb from its attachment and get a glass of ice water.

Attach the Touch Probe to the AccuTrak® VPE and touch the body of the TXV between the inlet and outlet with the tip of the probe. Hold the TXV bulb in your hand and listen to the way the valve moves internally. The valve must open smoothly. Similarly, while touching the TXV with the Touch Probe, drop the bulb in the glass of ice water. The valve must close. If the valve does not move or it moves with resistance, it must be replaced.

Attach the Touch Probe to the AccuTrak® VPE and touch the body of the TXV between the inlet and outlet with the tip of the probe. Hold the TXV bulb in your hand and listen to the way the valve moves internally. The valve must open smoothly. Similarly, while touching the TXV with the Touch Probe, drop the bulb in the glass of ice water. The valve must close. If the valve does not move or it moves with resistance, it must be replaced.

Total time to test: 5 - 10 minutes.

Technicians performing regular TXV inspections should consider upgrading to the AccuTrak® VPE-1000. The VPE-1000 features a dedicated touch probe sensor that provides significantly higher sensitivity and performance for touch probe applications.